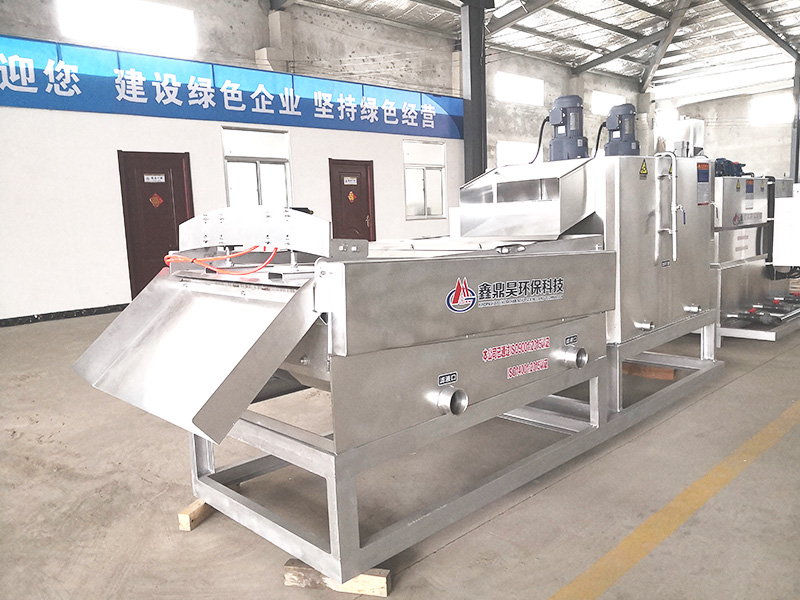

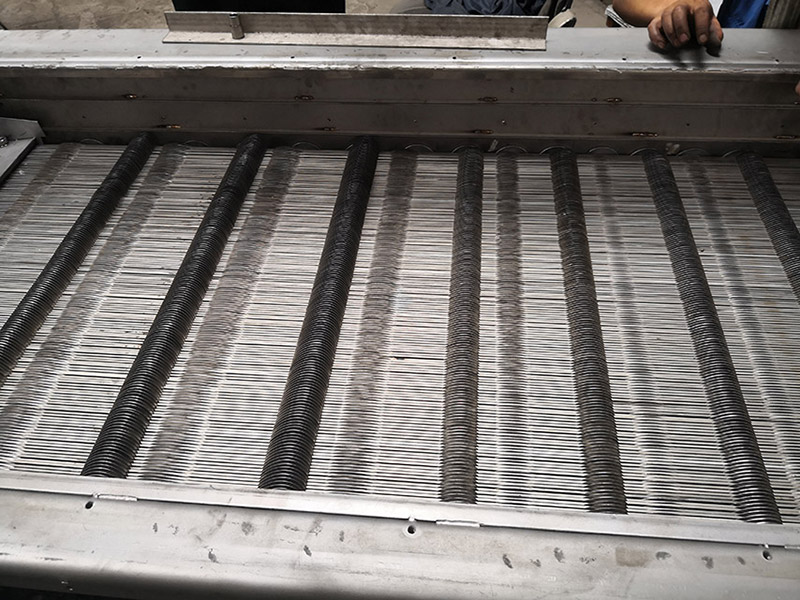

The flat plate sludge dewatering machine with laminated plates utilizes a uniquely designed self-cleaning filter gap principle of laminated plates to achieve an environmentally friendly, vibration-free and noise-free solid-liquid separation device.

Characteristics

It does not clog and there is no need to backwash the gaps. Through the continuous rotation of the continuously set laminated plates between the gaps, the separation of solid and liquid and self-cleaning occur simultaneously.

2. Stable processing capacity: Through self-cleaning of the filter gaps, it will not experience a decline in processing capacity due to clogging like other types of dewatering machines.

3. It has a powerful conveying capacity. Through the rotation of the stacked plates, it automatically conveys the separated solids.

4. Simple maintenance: Due to its simple structure, maintenance is also relatively easy.

5. The highly efficient double-stage flocculation agitator combines rapid flocculation with slow flocculation, making full use of chemicals and avoiding waste.

It can play a powerful role in various solid-liquid separation scenarios! The width of the gap can be adjusted according to different uses and processing objects to maximize its effectiveness.

Technical parameters

| 产品型号 | 公称处理尺寸(mm) | 双排转子数 | 处理能力m³/h | 固体产出 Kg-DS/h |

功率KW | |

| 10000mg/L | 30000mg/L | |||||

| XDHDP-312S | 300 | 12 | ≈5.5 | ≈2.6 | 40~80kg | 1.0 |

| XDHDP-512S | 500 | 12 | ≈12.0 | ≈5.5 | 80~160kg | 1.2 |

| XDHDP-712S | 700 | 12 | ≈18.0 | ≈8.0 | 120~240kg | 1.2 |

| XDHDP-912S | 900 | 12 | ≈24.0 | ≈10.0 | 150~300kg | 1.6 |

| XDHDP-1212S | 1200 | 12 | ≈30.0 | ≈14.0 | 240~420kg | 2.3 |

| ★The above processing capacity is a reference value. Depending on the nature of the sludge, the processing capacity may vary. For details, please consult our company when selecting the model | ||||||

| ★The above-mentioned processing capacity refers to the reference value based on the moisture content of the mud cake after dewatering at 78% to 85%. In some industries, there are special values of 56% and 63% | ||||||

| ★There is no upper limit to the sludge concentration, but the prerequisite is that it must have fluidity | ||||||

| ★The above-mentioned screw press dewatering machine is the standard configuration of our company. According to the nature of the sludge and the requirements of the customers, targeted specification changes can be made to further improve the performance of the dewatering machine in terms of processing capacity, moisture content, solid recovery rate, and operational stability. For more details, please consult our company. The most direct and accurate method for calculation and selection is to calculate based on the absolute dry mud as accurate. | ||||||