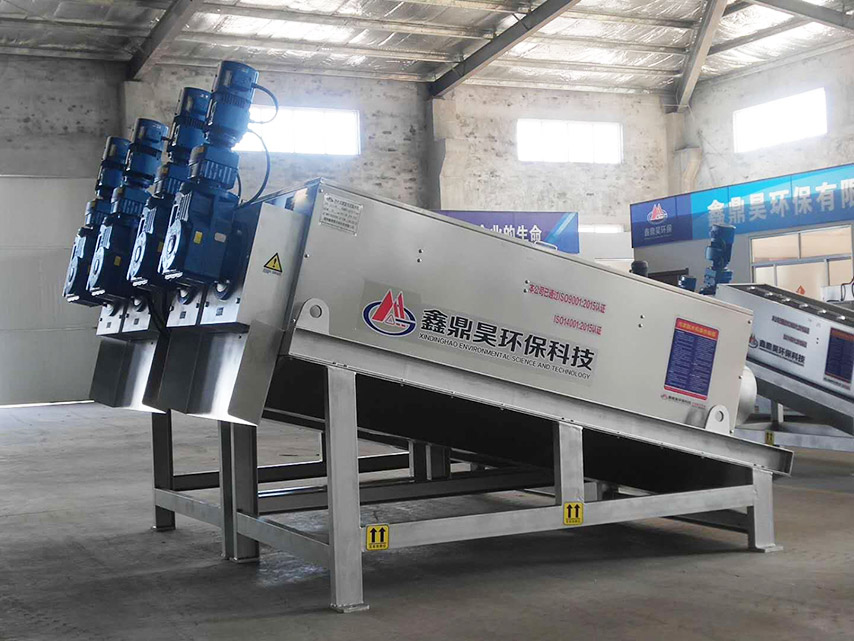

1、The product comes in a wide range of models and types, has a broad application scope, and is used in numerous sites

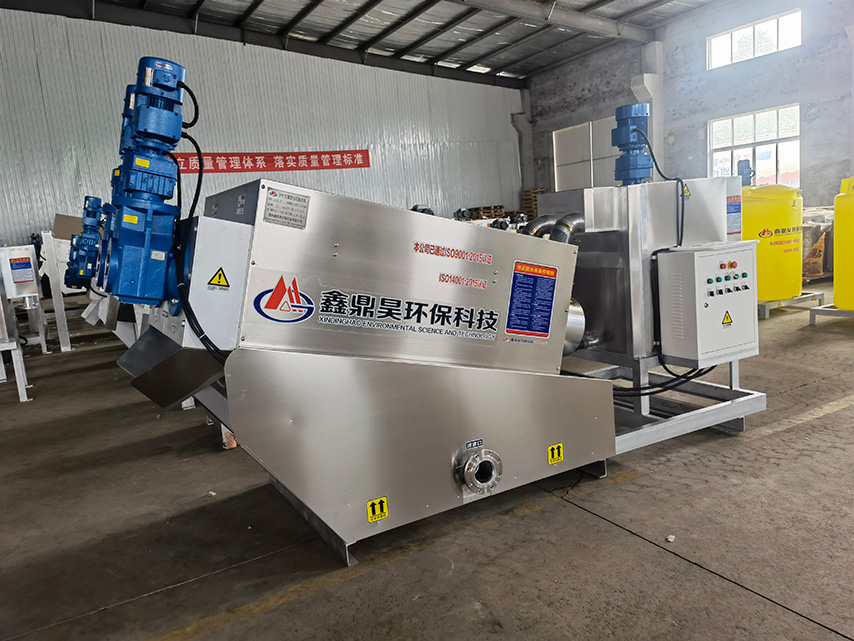

The screw press sludge dewatering machine is a device with unique design, low cost, low energy consumption, low operation speed, compact arrangement and small space occupation, high technical content and easy maintenance. Because it is relatively easy to move, it is mostly applied in sewage treatment stations, rural sewage treatment plants, small and medium-sized sewage treatment plants and other places.

The screw press sludge dewatering machine replaces the traditional filter cloth and centrifugal process with its unique and subtle filter body mode. It has reduced costs, improved efficiency and is deeply loved by a large number of users.

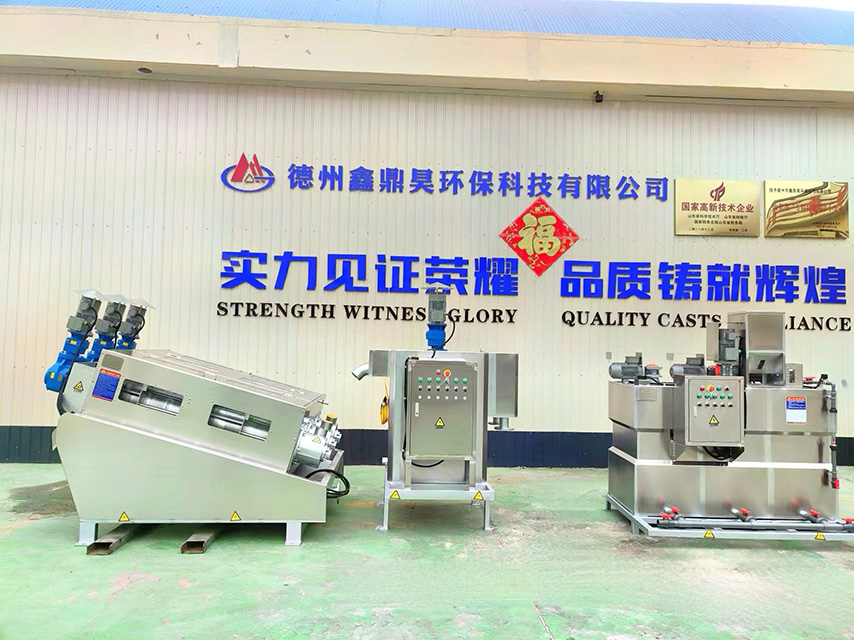

Our company has a group of experienced, meticulous and innovative technical and production personnel. Through our scientific management, our screw press sludge dewatering machines are sold all over the country, and high-quality products can be used everywhere.

Product model

| 产品型号 | DS标准处理量 | 污泥流量 | |||||

| 低浓度→高浓度 | 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| XDHDL101 | 6kg/h | 12kg/h | 0.8m3/h | 0.6m3/h | 0.4m3/h | 0.3m3/h | 0.2m3/h |

| XDHDL131 | 8kg/h | 15kg/h | 1.0m3/h | 0.8m3/h | 0.5m3/h | 0.4m3/h | 0.3m3/h |

| XDHDL132 | 16kg/h | 30kg/h | 2.0m3/h | 1.5m3/h | 1.0m3/h | 0.8m3/h | 0.5m3/h |

| XDHDL133 | 24kg/h | 45kg/h | 3.0m3/h | 2.3m3/h | 1.5m3/h | 1.2m3/h | 0.8m3/h |

| XDHDL201 | 12kg/h | 30kg/h | 3.0m3/h | 2.0m3/h | 1.3m3/h | 1.0m3/h | 0.7m3/h |

| XDHDL202 | 24kg/h | 60kg/h | 6.0m3/h | 4.0m3/h | 2.6m3/h | 2.0m3/h | 1.4m3/h |

| XDHDL203 | 36kg/h | 90kg/h | 9.0m3/h | 6.0m3/h | 4.0m3/h | 3.0m3/h | 2.1m3/h |

| XDHDL301 | 45kg/h | 75kg/h | 5.0m3/h | 3.8m3/h | 2.5m3/h | 2.0m3/h | 1.6m3/h |

| XDHDL302 | 90kg/h | 150kg/h | 10.0m3/h | 7.5m3/h | 5.0m3/h | 4.0m3/h | 3.0m3/h |

| XDHDL303 | 130kg/h | 225kg/h | 15.0m3/h | 11.0m3/h | 7.5m3/h | 5.6m3/h | 4.5m3/h |

| XDHDL351 | 100kg/h | 140kg/h | 10.0m3/h | 6.0m3/h | 4.3m3/h | 3.2m3/h | 2.6m3/h |

| XDHDL352 | 200kg/h | 280kg/h | 20.0m3/h | 12.0m3/h | 8.6m3/h | 6.4m3/h | 5.2m3/h |

| XDHDL354 | 300kg/h | 560kg/h | 38.0m3/h | 24.0m3/h | 17.0m3/h | 12.0m3/h | 10.0m3/h |

| XDHDL402 | 260kg/h | 360kg/h | 28.0m3/h | 18.0m3/h | 12.0m3/h | 9.0m3/h | 8.0m3/h |

| XDHDL403 | 380kg/h | 540kg/h | 42.0m3/h | 27.0m3/h | 18.0m3/h | 14.0m3/h | 12.0m3/h |

| XDHDL404 | 500kg/h | 720kg/h | 56.0m3/h | 36.0m3/h | 24.0m3/h | 18.0m3/h | 16.0m3/h |

规格尺寸

| 机型 | 外观尺寸(mm) | 总功率(kW) | 挡泥板距离地面 | 主轴变频 | 设计加药量 | ||

| L | W | H | |||||

| XDHDL101 | 2000 | 750 | 1300 | 0.75 | 390 | 0.37KW | 60L |

| XDHDL131 | 2300 | 750 | 1350 | 0.57 | 390 | 0.37KW | 72L |

| XDHDL132 | 2550 | 1050 | 1420 | 0.97 | 390 | 0.37KW | 144L |

| XDHDL201 | 2750 | 850 | 1600 | 0.92 | 550 | 0.55KW | 120L |

| XDHDL202 | 2900 | 1180 | 1600 | 1.65 | 550 | 0.55KW | 240L |

| XDHDL301 | 3700 | 1000 | 1960 | 1.5 | 640 | 0.75KW | 360L |

| XDHDL302 | 3900 | 1340 | 1960 | 2.25 | 640 | 0.75KW | 720L |

| XDHDL303 | 4000 | 1820 | 2090 | 3.35 | 640 | 0.75KW | 1080L |

| XDHDL304 | 4200 | 2200 | 2090 | 4.5 | 640 | 0.75KW | 1400L |

| XDHDL351 | 4100 | 1050 | 2200 | 2.2 | 700 | 1.1KW | 500L |

| XDHDL352 | 4300 | 1420 | 2200 | 3.3 | 700 | 1.1KW | 1000L |

| XDHDL354 | 4600 | 2200 | 2200 | 5.9 | 700 | 1.1KW | 2m3 |

| XDHDL402 | 4700 | 1580 | 2290 | 3.3 | 760 | 1.1KW | 1100L |

| XDHDL403 | 4900 | 2200 | 2290 | 4.4 | 760 | 1.1KW | 2m3 |

| XDHDL404 | 5300 | 2800 | 2290 | 5.9 | 760 | 1.1KW | 3m3 |

All the materials of the accessories are directly supplied by the raw material factory. There are stable domestic first-line enterprises as suppliers, ensuring quality and reducing costs. All stainless steel materials have numbers available for inquiry.

The main components of the equipment are processed by ourselves. All the professional production tools are independently developed and patented

The ring plates are directly taken as whole rolls in the steel plant to ensure the thickness of the ring plates. They are directly flattened and quickly cut into shape in one go using a high-power laser, without deformation. There is no transportation process in between, and the flatness is guaranteed. The gasket is made by grinding the sheet metal to the required size through an oil mill and then laser cutting it into shape in one go. Thus ensuring the gap.

The company was established in 2013 and began equipment research and development in 2009. Its predecessor was a mechanical processing enterprise that supplies parts to Sinotruk and China Railway. After a long period of development, the company has a large number of clients, a wide range of industries, and has accumulated a lot of professional technologies.

Second, it occupies a small space and has a high degree of automation

Compact design and simple operation, it can run unattended for 24 hours.

2. It occupies a small space and is easy to maintain and replace. Easy to move.

3. It has a self-cleaning function, requires less water for flushing, and is good at dewatering oily sludge.

Three, low power and high torque, low speed operation with fewer faults

(1) The rotational speed of the screw shaft is approximately 1 to 4 revolutions per minute, and it consumes low electricity.

(2) Few malfunctions, low noise and vibration, and safe operation;

(3) The daily maintenance time is short and the maintenance operation is simple.

Fourth, it features exquisite processing techniques and low usage costs

The single-machine dry sludge processing capacity DS can reach 6kg/h to 800kg/h (multiple sets of equipment can operate independently without affecting each other).

A uniform sludge and chemical agent mixer is set up in the coagulation tank to avoid chemical waste. It is equipped with a curved flow guide device to prevent the waste of chemicals.

The central shaft of the spiral shaft is integrally forged under high temperature and high pressure, ensuring the shaft's sturdiness and durability. The surface of the spiral blades undergoes wear-resistant surfacing welding and heat treatment processes, and the Vickers hardness of the contact surface can reach over 800 degrees. The spiral shaft is machined by a large lathe to ensure the concentricity and precision of the shaft. The secondary special lathe grinding and correction of the surfacing layer also serves to smooth the surfacing surface and reduce friction.

All gaskets are processed by CNC lathes, and the tolerance between the fixed ring and the movable ring is within 0.02mm.

The moving and fixed ring plates are cut by laser cutting machines, featuring high precision and have undergone polishing treatment to extend their service life. According to the special usage requirements of the customer, heat treatment can be carried out to increase the Vickers hardness of the ring plate by 1300 to 1500 degrees (while the conventional material table only has 990 degrees), further enhancing the corrosion resistance of the ring plate and preventing it from being corroded by reacting with chloride ions.

The main rotational speed can be adjusted by the frequency converter, with a speed range of 1 to 4 revolutions per minute. The deceleration device selects well-known domestic and foreign products with low noise and high efficiency to ensure stable quality and convenient maintenance.

The flushing device is composed of spray pipes and spray nozzles. The spray range covers the entire screw press body. Each nozzle can be replaced and it has a combination of manual and automatic adjustment methods.

The automatic control and protection function of the concentration and dewatering integrated machine is equipped with complete automatic monitoring, control and protection functions. The accessories adopt domestic and foreign technologies, ensuring safety.

The dehydration body of the modular design equipment adopts a modular design, which can be disassembled and assembled in sections as a whole. This greatly reduces the workload during equipment maintenance, repair and upkeep, making it more convenient.

The optional Settings are rich

According to industry demands, for models of different materials, targeted materials such as 304 stainless steel rings and plates that have undergone special heat treatment and inert gas anti-corrosion treatment by Xindinghao can be selected.

2. The model of the pipeline sludge and chemical mixer can be selected.

3. Models with multiple chemicals added;

4. Filtrate recovery model, saving operating costs;

5. Sludge concentration stable model;

6. Oily sludge treatment machine type;

7. Coarse fiber processing machines, etc.

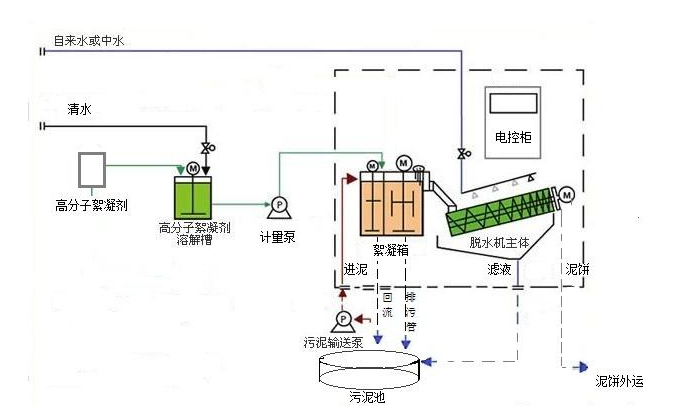

Construction principle

The main body of the dehydrator's screw press is a filtering device formed by the interlacing of fixed rings and moving rings, with a screw shaft running through them. The front section is the concentration section and the rear section is the dehydration section.

The filter gap formed between the fixed ring and the moving ring and the pitch of the screw shaft gradually decrease from the concentration section to the dewatering section. The rotation of the screw shaft not only propels the sludge from the concentration section to the dewatering section but also constantly drives the moving rings to clean the filter gaps, preventing clogging.