I. Product Introduction

Flocculants are frequently used dosing chemicals in water treatment, and they are generally organic high-molecular substances. During the dissolution process of these substances in water, due to their high viscosity, the dissolution process often becomes complicated, and they are prone to caking, which increases the intensity of manual operation and reduces the degree of automation in dosing.

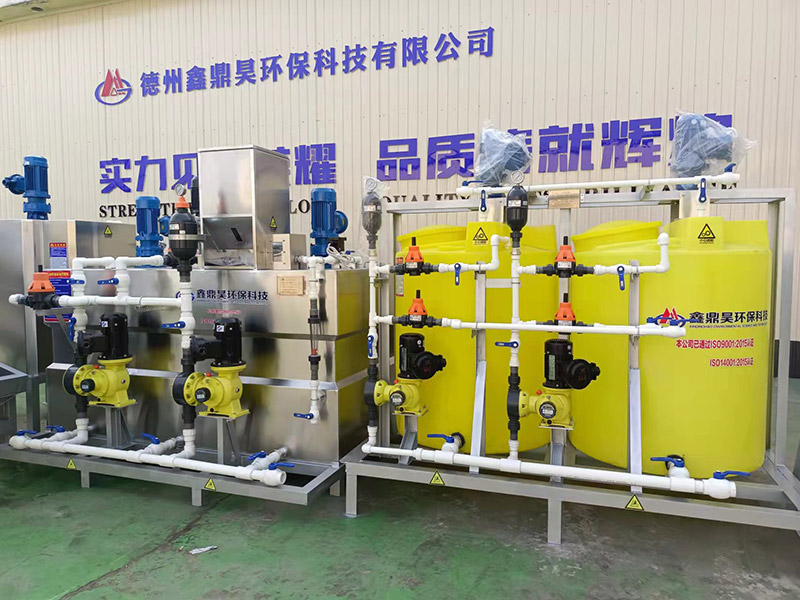

To solve such problems, Dezhou Xindinghao Environmental Protection Technology Co., Ltd. has developed the XDHJY series of fully automatic dosing machines and integrated flocculant preparation devices based on the absorption of advanced process technologies. The fully automatic dosing machine is a fully automatic dosing system integrating drug dissolution, maturation and dosing. This equipment controls the dosage of the required chemical solution based on its concentration, automatically stirring, dissolving and maturing the flocculant, and then adding it to the treated water by the dosing pump. This reduces the complexity of the flocculant usage process, makes the dosing process automatic and accurate, and saves the dosage of chemicals.

The XDHJY series of fully automatic dosing machines take up little space, are easy to install, have a high degree of automation and a long service life. They can be widely used in water treatment in urban water supply treatment, sewage treatment and power industries, truly eliminating the troubles caused by chemical dosing for users.

Ii. Product Parameters

PAM automatic medicine soaking machine

The PAM automatic medicine soaking machine gradually completes the medicine soaking through the classification of each solution tank. The solution tanks are isolated from each other to ensure the optimal reaction time and constant concentration in each solution tank, and the S-line connection configuration. The automatic control system is connected to the liquid level controller on the storage tank. Once the liquid level reaches a low position, the machine will automatically open the water inlet solenoid valve and start the dry powder machine to add dry powder flocculant. When the liquid level reaches its highest point, the equipment will automatically stop water inflow and chemical addition.

| 自动加药机型号 | 制备能力(L/h) | 外观尺寸(mm)不含泵 | 总功率(kW) | 运行重量(kg) | ||

| L | W | H | ||||

| XDHJY-1000 | 1000 | 1650 | 1020 | 1800 | 1.47 | 1600 |

| XDHJY-1500 | 1500 | 1850 | 1220 | 1800 | 2.62 | 2200 |

| XDHJY-2000 | 2000 | 2350 | 1220 | 1950 | 2.62 | 3000 |

| XDHJY-3000 | 3000 | 2350 | 1640 | 1950 | 3.67 | 4200 |

| XDHJY-4000 | 4000 | 3050 | 1640 | 2000 | 3.67 | 7000 |

| XDHJY-6000 | 6000 | 4050 | 1900 | 2000 | 4.89 | 9000 |

| XDHJY-8000 | 8000 | 4050 | 1900 | 2500 | 6.97 | 12000 |

Manual medicine soaking bucket

The manual medicine soaking bucket is a simple medicine soaking device made of PE material, consisting of a stirring motor, a stirrer, a dosing port, a water inlet and a PE bucket. It is easy to operate, has a low cost, is corrosion-resistant, and is suitable for operation under the supervision of personnel in small-scale projects.

| 型号 | 制备能力(L/h) | 外观尺寸(mm)不含泵 | 总功率(kw) | 运行重量(kg) | ||

| L | W | H | ||||

| XDHJY-500PE | 500 | 860 | 860 | 1470 | 0.55 | 60 |

| XDHJY-1000PE | 1000 | 1110 | 1110 | 1570 | 0.75 | 70 |

| XDHJY-1500PE | 1500 | 1260 | 1260 | 1840 | 0.75 | 100 |

| XDHJY-2000PE | 2000 | 1400 | 1400 | 2090 | 1.5 | 120 |

三.工作原理

2.1系统组成

XDHJY系列一体化絮凝剂制备装置主要由箱体、干粉进料机和自动控制系统三部分组成。

2.1.1 箱体

箱体由PP或SUS304材料制成,分为三格(XDHJY-500型设备箱体分为两格),即制备格、熟化格和投配格,每格装有1个电动搅拌器,便于充分混和药液。在投配格中装有液位计,检测高和低液位,保证整个系统不间断供药。在制备格上还有一个混合器,起到浸润药剂的作用。

2.1.2 干粉进料机

干粉进料机包括料斗、进料电机、投配螺旋和混合器。电机由控制箱内的变频器调整转速,从而控制投配螺旋的转速,调整投加药量,控制制备药液的浓度。

2.1.3 自动控制系统

自动控制系统主要包括控制箱、各种传感器(如液位计、料位计)和控制部件。通过它实现全自动控制——全自动运行、报警、停止及再启动。自动控制系统使整套设备安全运行,从而延长设备使用寿命。

2.2工作原理

絮凝剂干粉倒入干粉进料机的料斗,通过改变进料电机3的转速来精确控制进药量。干粉由投配螺旋经过输料管推入到混合器中,输料管的电热带能使里面的干粉避免受潮结块堵塞输料管。进入混合器中的干粉立刻被稀释水润湿,并滑入制备格,制备格中有一个缓缓转动的电动搅拌器,初步混和药液,然后药液再流入熟化格,在其内充分混和并熟化,熟化后的药液,流入投配格中,为防止熟化的药液发生沉淀,投配格中的搅拌器在停止制备药液时进行间歇搅拌。

当絮凝剂制备时,熟化格中的搅拌器停止转动,防止新流入的药液和已经熟化好的药液混和,影响絮凝效果;当制备停止后,熟化格中的搅拌器重新启动,将刚进入熟化格的药液熟化。投配格中安装了液位计,当投配格液位低于设定液位时,加药系统开启,制备新的药液;反之,投配格中到达最高设定水位时,为防止溢流,系统停止运转。