First, the product models and models, a wide range of applications, the use of many

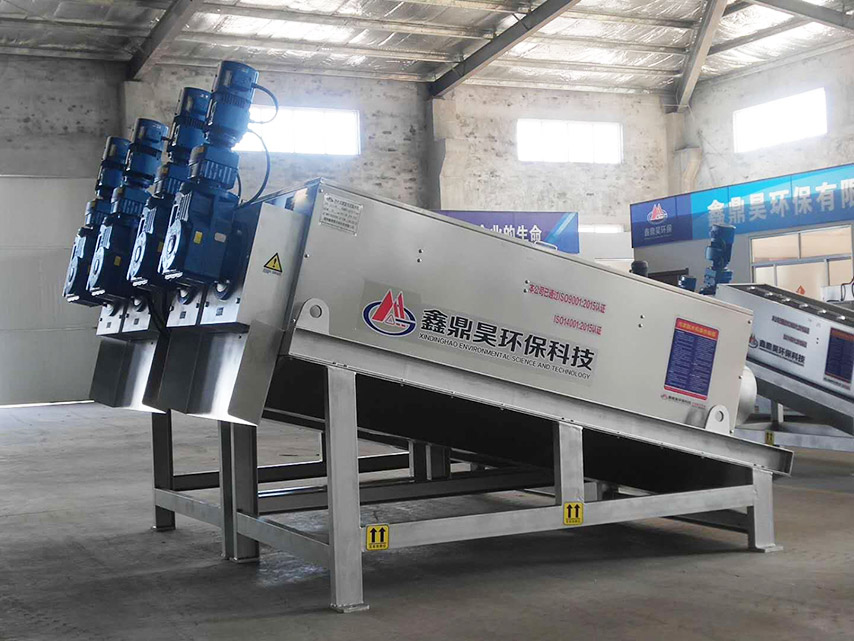

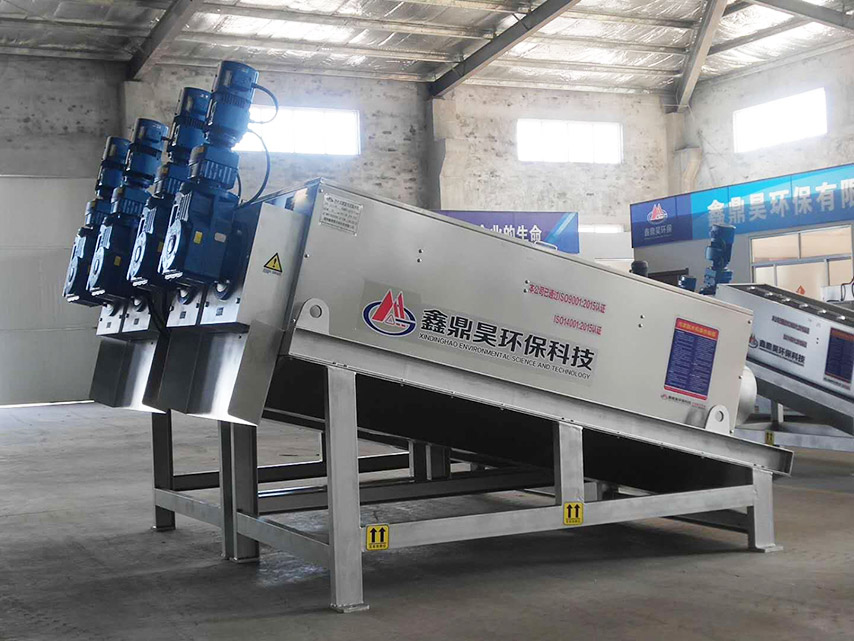

Cascade sludge dewatering machine is a unique design, low cost, low energy consumption, low operation, compact arrangement and small space, high technical content, easy to maintain a kind of equipment. Because it is more convenient to carry, it is mostly used in sewage treatment stations, township sewage plants, small and medium-sized sewage plants and other places.

The spiral sludge dehydrator uses its own unique and subtly aligned filter body mode to replace the traditional filter cloth and centrifugal process. It reduces the cost and improves the efficiency, and is loved by the majority of users.

The company has a group of experienced, rigorous, innovative technicians and production personnel, through our company's scientific management, so that our stack screw sludge dehydrator sales all over the country, can use good products.

Product model

Size

11 patents of whole machine, 5 patents of professional production tools, and passed: ISO9001-2015; Iso 14001-2015 Certification

All accessories materials are directly supplied by the raw material factory, there is a stable domestic first-line enterprises as suppliers, quality assurance, cost reduction, all stainless steel materials are numbered for inquiry.

The main parts of the equipment are processed by themselves, and the professional production equipment is independently developed and patented

The ring sheet is directly taken in the steel mill, to ensure the thickness of the ring sheet, directly open and use high power laser to quickly cut a molding, will not change the shape, there is no transportation process in the middle, the flatness is guaranteed; Gasket from the plate through oil grinding oil grinding to size, laser cutting molding. To ensure the gap.

The company was founded in 2013, began equipment research and development in 2009, formerly a mechanical processing enterprise, with heavy truck and China Railway supply parts. The company has experienced long-term development, many customers, a wide range of industries, and accumulated a lot of professional technology.

Second, small footprint, high degree of automation

1. Compact design, simple operation can achieve 24 hours of unmanned operation.

2. Small footprint, easy to repair and replace; Easy to handle.

3. With self-cleaning function, self-cleaning function, less water consumption, good at the dehydration of oily sludge.

Three, small power, high torque, low speed operation less fault

(1) The rotation speed of the spiral shaft is about 1~4 RPM, low power consumption;

(2) less fault, small noise and vibration, safe operation;

(3) The daily maintenance time is short and the maintenance operation is simple.

Four, exquisite processing technology, low cost

Single-machine dry mud handling DS up to 6kg/h— 800kg/h (multiple groups of equipment each group can operate independently, and do not affect each other).

Coagulation tank A uniform mud mixer is set up to avoid drug waste. It is equipped with a curvilinear diversion device to avoid chemical waste.

spiral axis The central shaft is made of high temperature and high pressure forging to ensure the shaft is strong and durable. The surface of the spiral blade is made of wear-resistant surfacing welding and heat treatment process, and the Vickers hardness of the contact surface can reach more than 800 degrees. The spiral shaft is turned by a large lathe to ensure the concentricity and accuracy of the shaft. The secondary special lathe grinding corrects the surfacing layer, and also plays a role in smoothing the surfacing surface and reducing friction.

gasket All are machined by CNC lathes, and the tolerance between the fixed ring and the movable ring is within 0.02mm.

moving ring tablet Cut by laser cutting machine, high precision, and after polishing treatment to increase the service life. According to the special requirements of customers, heat treatment can be carried out to increase the Vickers hardness of the ring sheet by 1300 to 1500 degrees (conventional material table is only 990 degrees), which further enhances the corrosion resistance of the ring sheet, so that the ring sheet does not react with chloride ions and is corroded.

Main speed It can be adjusted by the frequency converter, the speed is 1 to 4 RPM /min, and the deceleration device uses well-known products at home and abroad with low noise and high efficiency to ensure stable quality and easy maintenance.

flushing device It is composed of spray pipe and spray nozzle, and the spray range covers the whole stack screw body. Each nozzle can be replaced, and the adjustment mode is combined with manual automatic.

Automatic control and protection function Concentration dewatering machine has perfect automatic monitoring, control and protection functions, accessories using domestic and foreign technology, safety is guaranteed.

Modular design The dewatering body of the equipment adopts modular design, which can be disassembled and assembled in different sections, greatly reducing the workload and making it easier to repair, maintain and maintain the equipment.

Optional Settings:

1, according to the needs of the industry, different materials of the model, can choose through the special heat treatment of inert gas anti-corrosion treatment of 304 stainless steel rings with targeted materials;

2, can choose the type of pipeline mud mixer;

3, adding a variety of pharmaceutical models;

4, filtrate recovery model, saving operating costs;

5, sludge concentration stable model;

6, oily sludge treatment machine;

7, coarse fiber processing models, etc.

Construction principle

The main body of the dehydrator is a filter device formed by the fixed ring and the floating ring overlapping each other, and the spiral shaft running through it. The front part is the enrichment part and the back part is the dehydration part.

The filter gap formed between the fixed ring and the floating ring and the pitch of the spiral shaft gradually decrease from the concentration part to the dehydration part. The rotation of the spiral shaft pushes the sludge from the thickening part to the dewatering part, and also continuously drives the traveling ring to clean the filter joint and prevent clogging.